The "How CMMS Can Help Streamline Maintenance Operations and Reduce Costs" Ideas

CMMS vs. Traditional Maintenance Management: Which is Ideal for Your Business?

Servicing control is a vital facet of any kind of service that relies on machinery and devices for its operations. It entails the program, scheduling, and execution of maintenance tasks to make sure superior efficiency, integrity, and safety of tools. Commonly, servicing management was carried out manually utilizing spread sheets or paper-based bodies. Nevertheless, with the dawn of digital upkeep control systems (CMMS), businesses right now possess a much more reliable and automated means of handling their upkeep activities. In this message, we will certainly be matching up CMMS versus standard upkeep management to help you identify which one is right for your business.

What is CMMS?

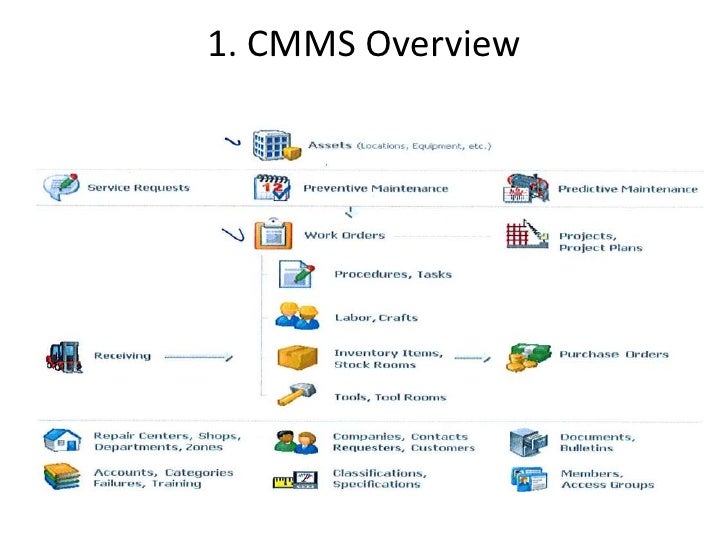

A digital maintenance management device (CMMS) is a software application application designed to streamline and automate upkeep management jobs. It permits businesses to track and take care of their tools, inventory, work purchases, precautionary servicing schedules, resource past history, and a lot more coming from a single system. Along with CMMS program in spot, businesses can easily simply check the health and wellness of their devices in real-time and rapidly identify potential issues before they become major complications.

Advantages of CMMS

One of the principal perks of making use of a CMMS over traditional routine maintenance control techniques is that it simplifies procedures through automating several tasks that were recently performed by hand. Key Reference spares opportunity but likewise minimizes errors affiliated with manual information access.

Another conveniences is that it provides real-time exposure in to devices performance by means of dashboards and reports, making it possible for services to help make data-driven selections about their routine maintenance approaches. This allows them to optimize their information by centering on crucial properties that need immediate focus while lowering needless downtime created through reactive fixings.

Also, it helps organizations conform with governing requirements through providing records on job performed on each property such as evaluation files or audit route.

Downsides of CMMS

While there are actually a number of benefits affiliated along with using a CMMS body for your service's maintenance needs, there are actually likewise some prospective drawbacks to consider. One of the primary disadvantages is that it may be pricey to implement, especially for small services with limited finances.

There might additionally be a learning arc associated with utilizing the software application, which may lead to protection from workers who are made use of to standard routine maintenance monitoring procedures such as paper-based devices.

Finally, some businesses might not have accessibility to reliable world wide web connection or components that is compatible along with the CMMS software application, which might restrict its effectiveness.

What is Traditional Maintenance Management?

Standard servicing control includes personally tracking and dealing with devices and stock utilizing spreadsheets or paper-based units. It normally includes sensitive servicing where devices is only fixed when it breaks down. Precautionary servicing activities are typically done located on a repaired schedule instead than data-driven ideas.

Perks of Traditional Maintenance Management

One advantage of typical routine maintenance management techniques is that they may be less costly than implementing a CMMS unit. Paper-based units need little to no expenditure in innovation and may be handled through employees without specialized training.

One more conveniences is that these strategies might be more knowledgeable and relaxed for employees who have been making use of them for years. This might potentially reduce resistance or pushback coming from staff participants who are unwilling to transform their processes.

Negative aspects of Traditional Maintenance Management

The largest negative aspect of standard routine maintenance control techniques is the lack of computerization and real-time data insights accessible along with CMMS software program. This means that businesses relying on these techniques often run reactively, resulting in greater downtime costs as a result of to unexpected tools breakdowns.

Additionally, there is a higher potential for error with manual data entrance procedures such as spread sheets or paper-based bodies. This can easily lead in shed work purchases or insufficient reports, leading to further inefficiencies and potential security dangers.

Which One Is Ideal For Your Service?

Opting for between CMMS vs conventional upkeep management mostly depends on your service's special demands and finances restraints. If you have a large quantity of equipment that requires regular monitoring, normal preventative routine maintenance routines, or require real-time data ideas, at that point a CMMS system might be the correct option for you.

On the various other palm, if you possess a smaller company with much less sophisticated equipment and stock necessities, and don't call for real-time record insights, standard maintenance management techniques may be sufficient.

Essentially, the objective of any sort of routine maintenance monitoring technique is to ensure optimal functionality of devices while reducing recovery time and routine maintenance costs. Through weighing the advantages and negative aspects of each approach against your particular organization necessities, you can easily figure out which approach is correct for you.